Products

- Metallurgy

-

Metallurgy

PJSC “KZTS” produces for ironworks roll-turning and roll-grooving machines for processing of forming rolls with maximum diameter from 650 to 2950 mm and weight from 16 to 100 ton, roll-grinding machines for processing of rolls up to 2500 mm in diameter, roll-building-up machines for recovery of mill rolls with roll body diameter from 250 to 1400 mm by means of electric-arc building-up, machines for boring and grinding of forming rolls assembled with mill stand of cold tube rolling, as well as for boring and grinding of pilger mill rolls, centerless turning machines for processing of bar with diameter from 12 to 360 mm.

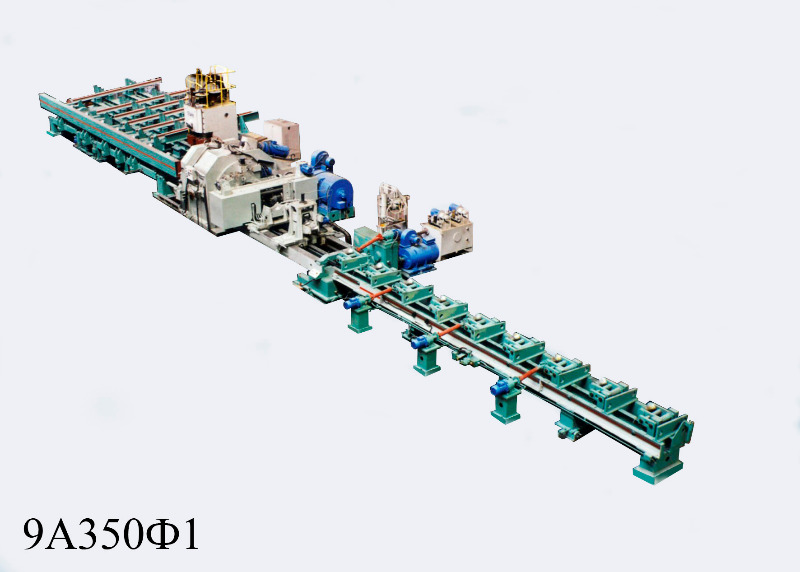

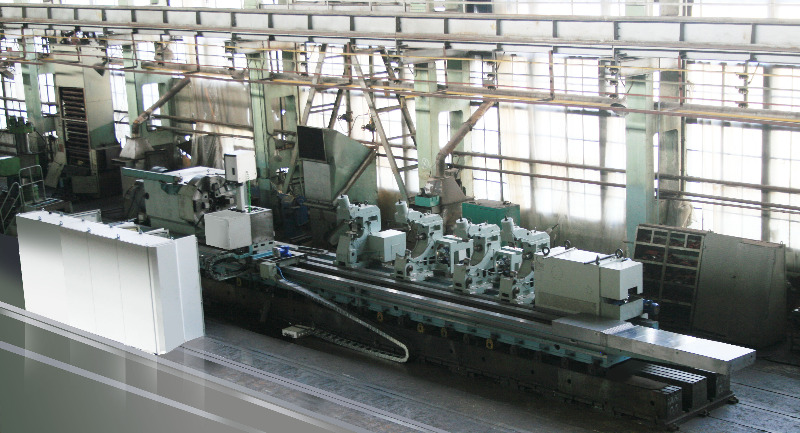

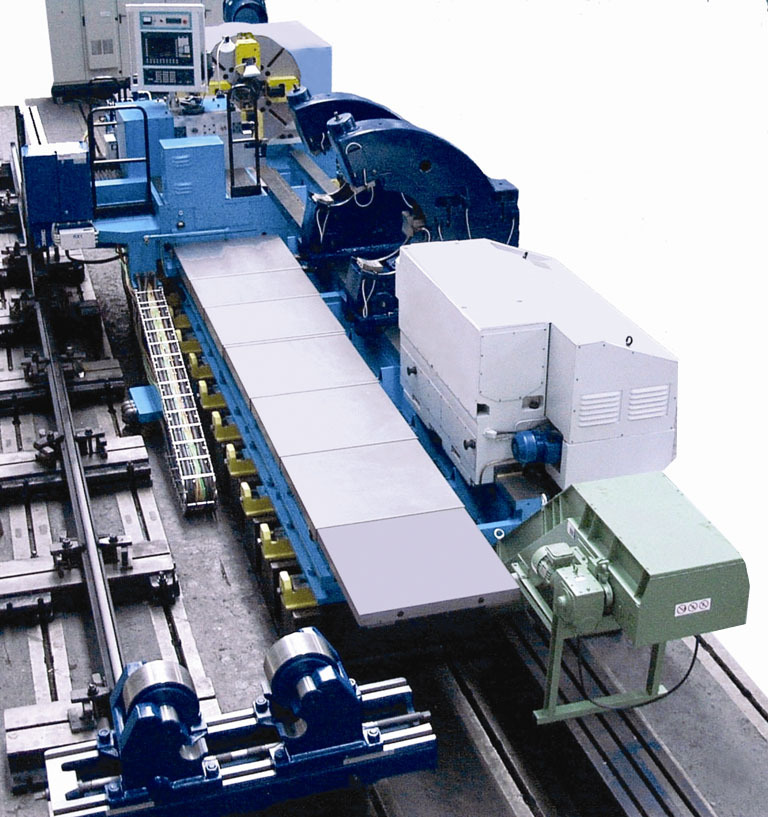

Centerless turning machine mod.КJ9350Т is designed for centerless processing of rounds

Centerless turning machine mod.9А350f1

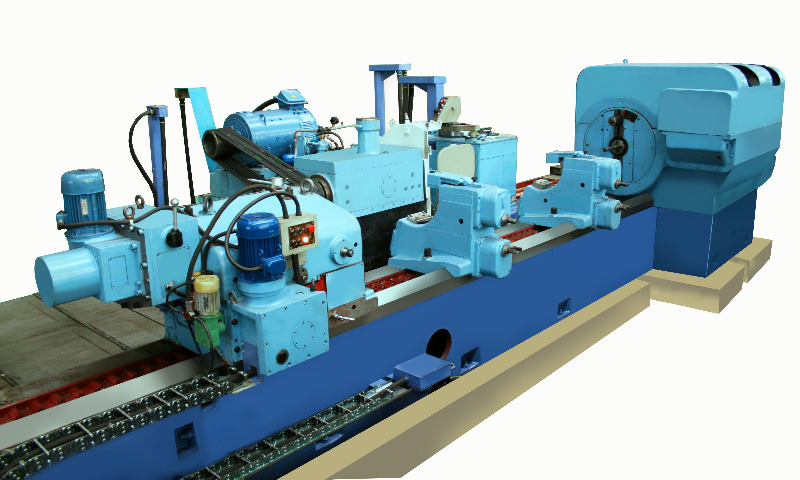

Roll-grinding machine mod. 3415Е. The machine is designed for external grinding of cylindrical, conical, convex and concave surfaces of mill rolls. - Power Industry

-

Power Industry

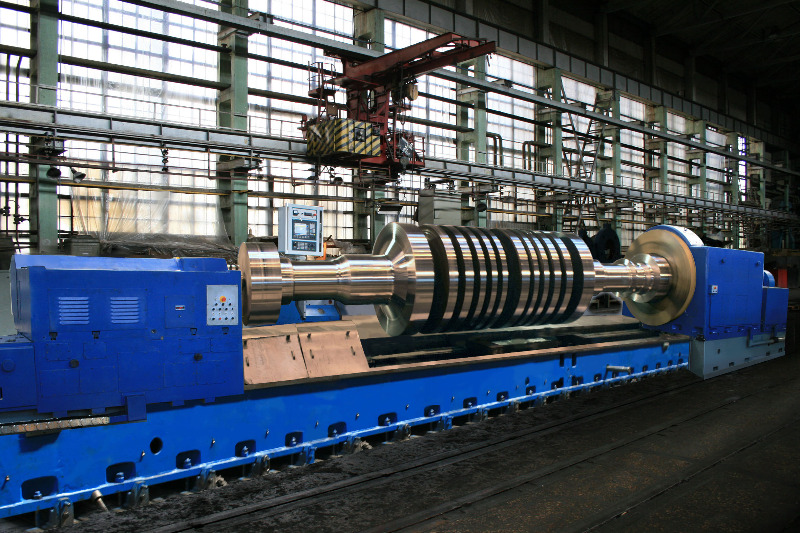

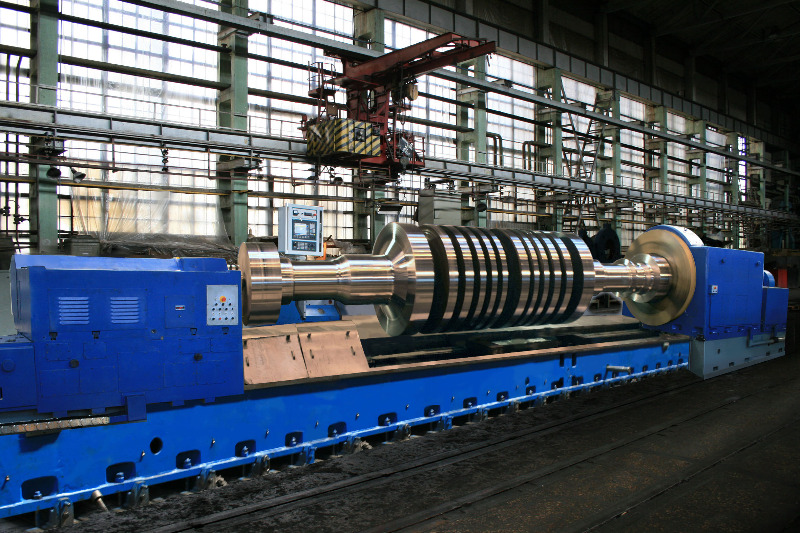

PJSC “KZTS” is the biggest designer and manufacturer of heavy, unique and special machine tools in the world. Heavy-duty lathes with maximum processing diameter from 500 to 6300mm and workpiece weight from 6 to 250ton, surfacing lathes with processing diameter up to 3200mm, machines designed for processing of ship rolls with neck diameter up to 800mm and weight up to 150ton, are successfully used in the biggest enterprises of atomic and power industry, shipbuilding.

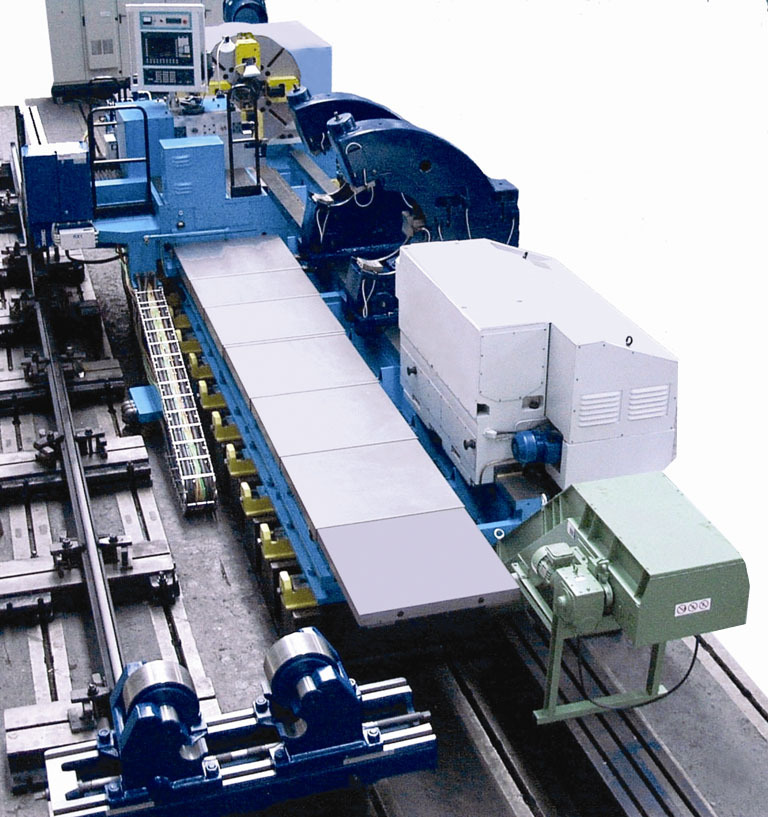

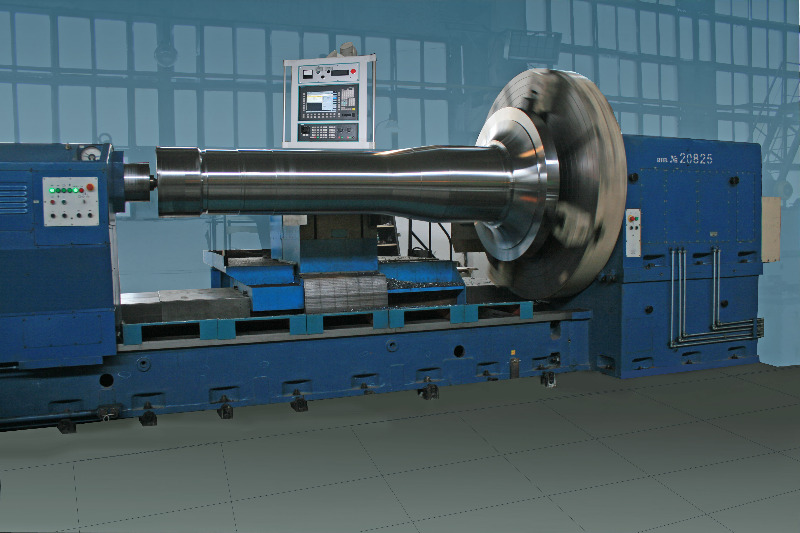

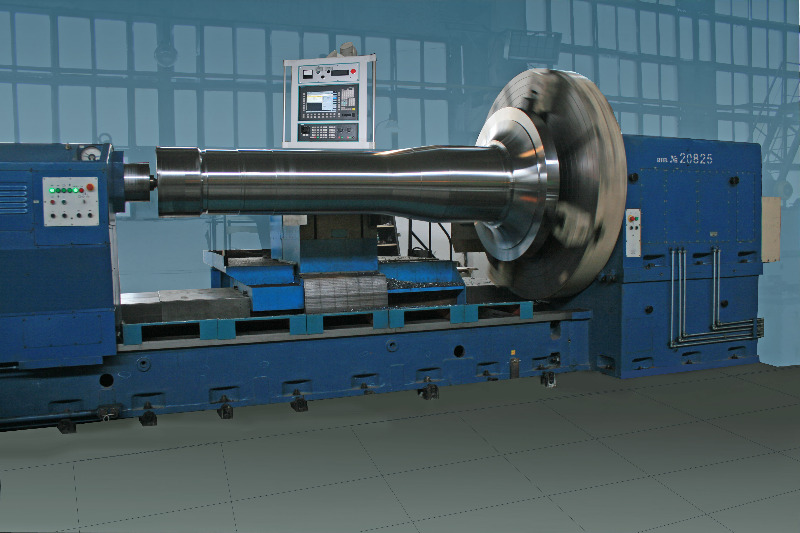

Heavy-duty lathe with CNC mod. КJ16274f3 is designed for roughing and finishing of turbine rotors, hydraulic shafts, cylinders, generator shafts.

Heavy-duty lathe with CNC mod. 1К670f3 is designed for finish and rough turning of workpieces made of steel, cast iron and other materials according to program.

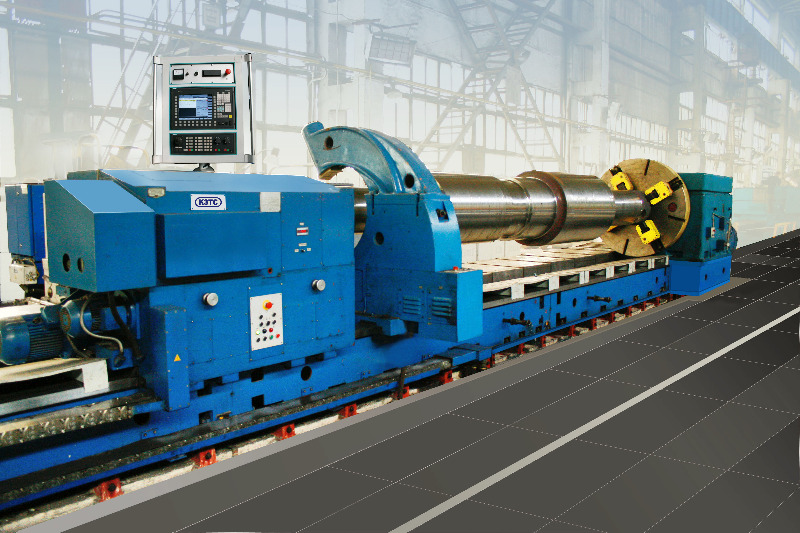

Heavy-duty lathe with CNC mod. КJ16165f3 is designed for processing of shafts, axles as well as for thread cutting by means of cutters equipped with carbide blades.

- Railway Transport

-

Railway Transport

PJSC “Kramatorsk Heavy Duty Machine Tool Building Plant” is practically a sole company which produces machines, automated lines and special machines for processing of axles and wheelsets of rolling stock, lifters of pair of wheels for railway transport companies of Ukraine, CIS countries.

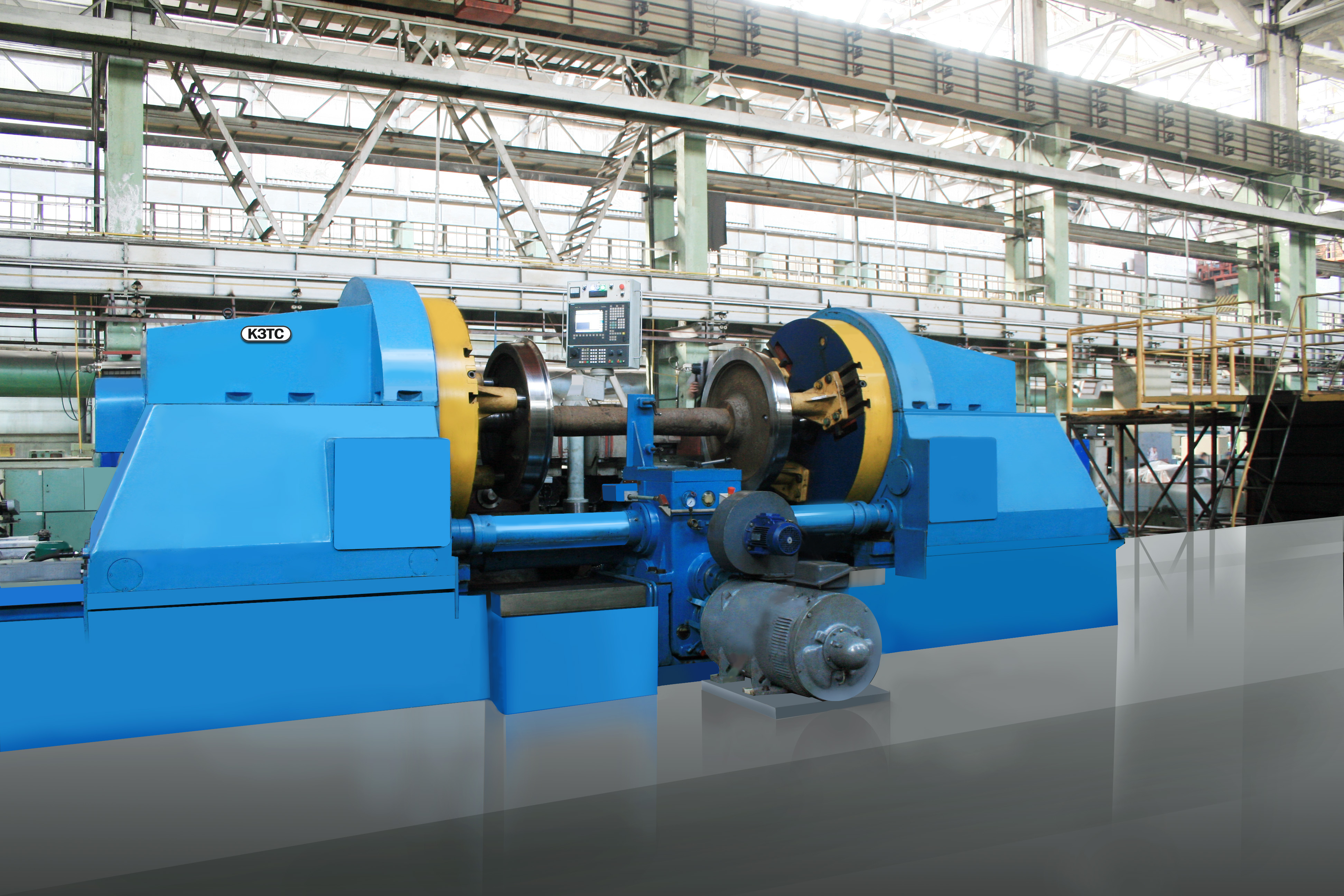

Wheel-turning lathe mod. 1836.М.10Wheel-turning lathes mod. 1836.M10 which are well-known in many countries are designed for processing of dismantled wheelsets 840-1250mm in diameter. They have classic arrangement of lathe and are designed for processing of new and recovery of worn-out wheelset tyre profiles of waggons, locomotives, electric locomotives, diesel locomotives and underground railway carriages.

Special wheel-milling machine mod. КJ20Тf1 is designed for milling works for repair of profile of two wheelset tyres of railway transport rolling stock, without removing out of locomotives, electric locomotives, diesel locomotives and motor car units.. - General Engineering

-

General Engineering

The company is one of the biggest manufacturers of heavy-duty lathes and unique machines.

The range of heavy-duty lathes is a result of creative search of all staff, use of operating experience of earlier machines, research and experiments. New advanced models of heavy-duty lathes of extended precision with CNC are used widely in general engineering of Ukraine and in neighboring and far-abroad countries.

This is the range of machines:

Machine mod. 1К675f3 is designed for finishing and roughing of workpieces made of steel, cast iron and other materials.

Machine mod. 1К665f3 is designed for processing of rotation body parts.

Heavy-duty lathe with CNC mod. КJ16165f3 is designed for processing of shafts, axles as well as for thread cutting by means of cutters equipped with carbide blades.

Heavy-duty lathe with CNC mod. 1К670f3 is designed for finish and rough turning of workpieces made of steel, cast iron and other materials according to program.

Heavy-duty lathe with CNC mod. КJ16274f3 is designed for roughing and finishing of turbine rotors, hydraulic shafts, cylinders and generator shafts.